Kato Science Corner x Metrolab GZM.

Submitted by SUT_blog on Mon, 04/22/2024 - 14:15Popular science lecture for the inhabitants of Katowice as part of the Kato Science Corner x Metrolab GZM.

Popular science lecture for the inhabitants of Katowice as part of the Kato Science Corner x Metrolab GZM.

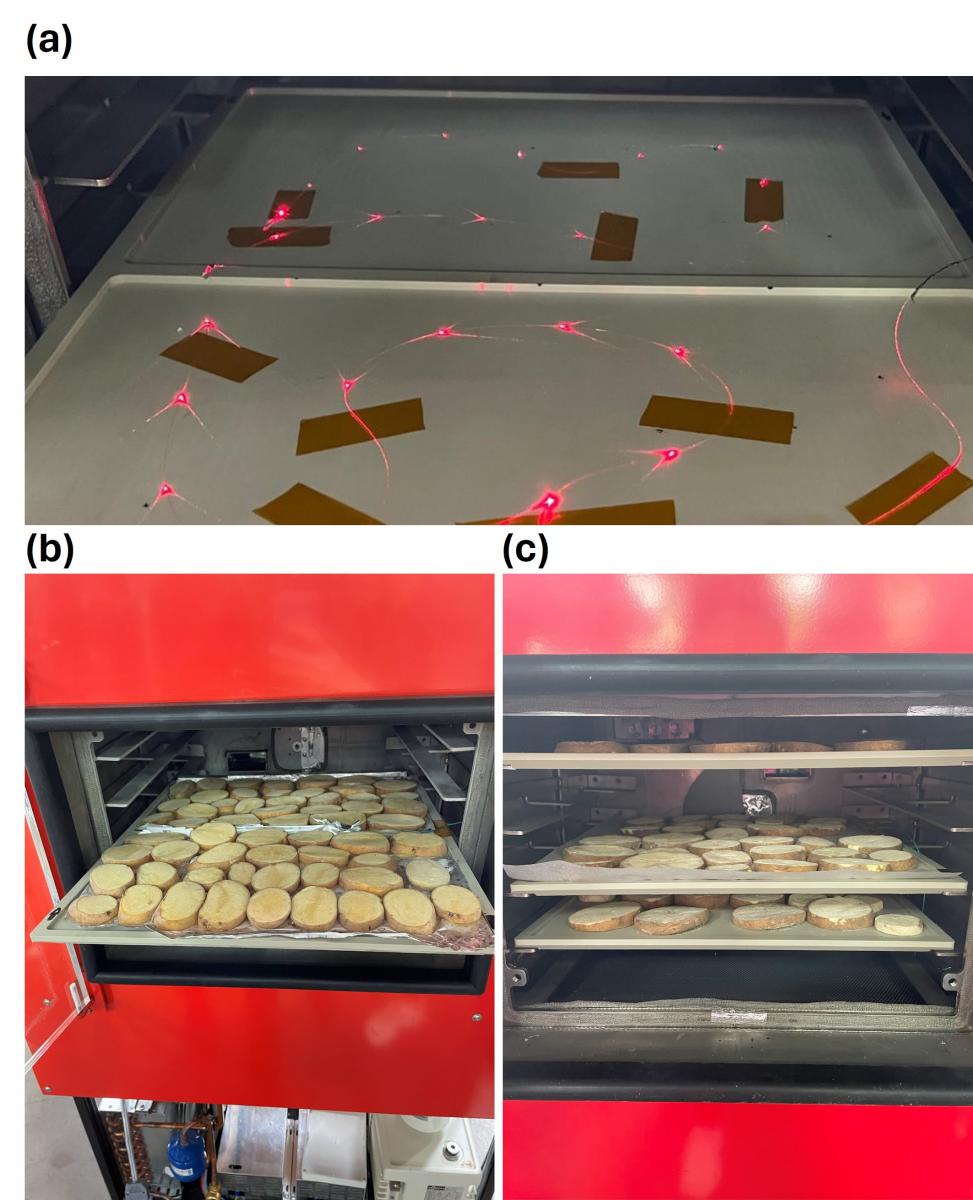

Preparation of the food sample (a) location of the fiber optic temperature sensors on the shelf, (b) placing one-centimeter potato slices on the shelf with fiber optic temperature sensors and (c) placing three trays with products in the chamber

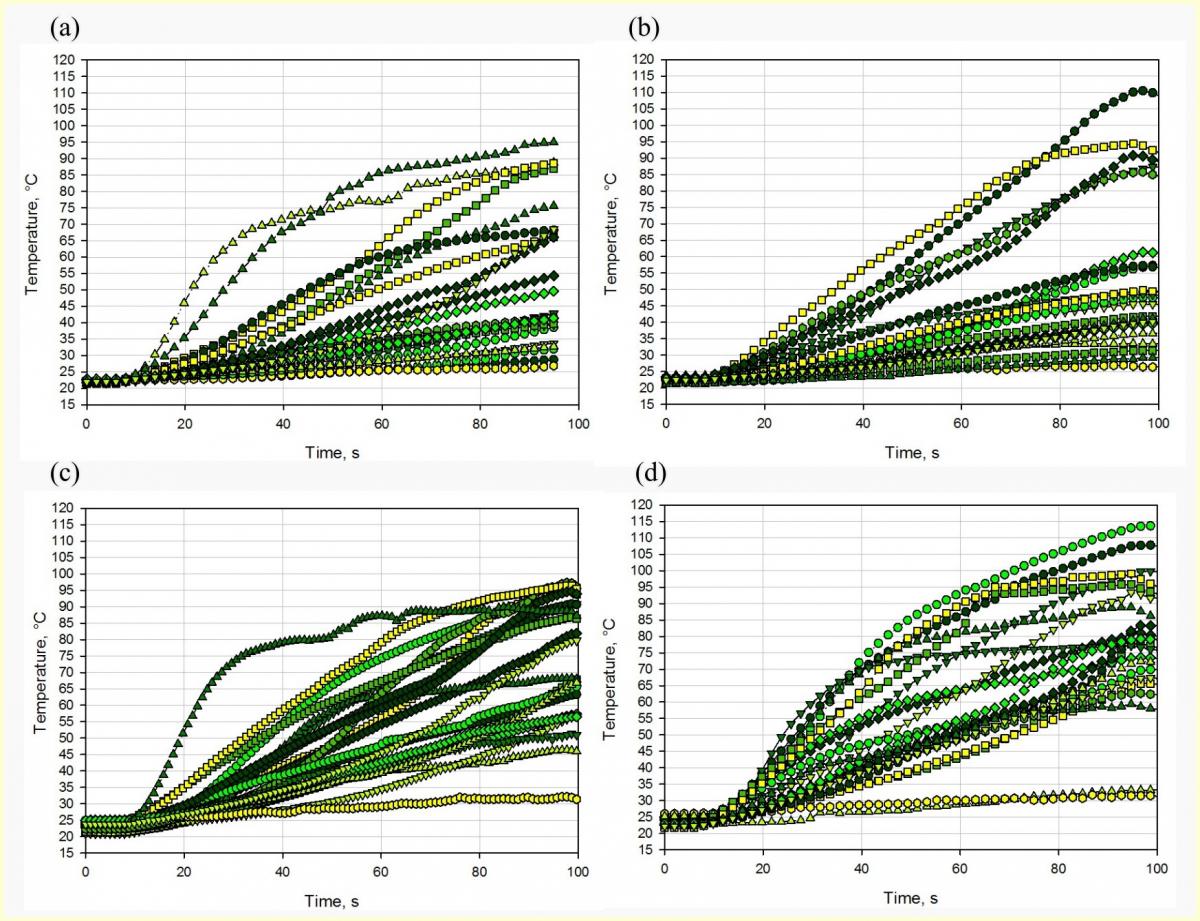

For the prototype chamber, experiments were carried out taking into account four different configurations of magnetron operation (top only, bottom only, both and both with a MW mixer). Fugures below shows the temperature profiles for each analysed configuration and photos of food samples after the process.

The chamber is made of stainless steel, and there are five teflon shelves placed inside, supported on frames on both sides of the chamber (see Fig. below), on which food products can be placed. The location of the shelves relative to the reference chamber remained unchanged. On the back wall of the chamber there are MW windows in through which microwaves enter to the chamber with food products, and MW mixer which ensure uniformity of the MW field.

On Wednesday, September 6, our PhD candidate Edyta Piechnik, had the pleasure of presenting paper "Numerical Analysis of Food Freezing and Airflow Distribution in a Home-Scale Freeze Dryer" at the 14th International Conference on Computational Heat and Mass Transfer (ICCHMT 2023), which took place in Düsseldorf, Germany. The conference was held by Düsseldorf University of Applied Sciences

FrostWave project at the ICR2023 Refrigeration Congress organized by IIFIIR - International Institute of Refrigeration!❄

Project representatives participated in the ICR2023 Refrigeration Congress, where our PhD candidate Edyta Piechnik gave a presentation entitled "Prototype of domestic-scale freeze-dryer with natural working fluid-based refrigeration system and microwave heating system". Both experimental and numerical activities that led to the creation of the concept of a prototype freeze dryer, which is currently under construction, were discussed.

We are pleased to present the final concept of a prototype freeze dryer equipped with a microwave heating system and a refrigeration system based on a natural refrigerant. Several months of numerical analysis of microwave distribution, structural and air flow, as well as experimental activities on the new refrigeration system, led the FrostWave team to the following chamber design.

Another important aspect that was taken into account when designing a prototype freeze dryer equipped with microwaves was to ensure even air distribution over each of the shelves filled with food products. For this purpose, flow analyzes were performed using a CFD model that was created in the first stages of the project. Several configurations of the position of fans and air guides were considered. The final design allowed for equalizing the air velocity fields in such a way that a velocity > 1 m/s was achieved over each shelf.